In the quest for sustainable energy solutions, the wood pellet machine stands out as a beacon of innovation. This remarkable piece of equipment is at the forefront of biomass new energy source technology, transforming organic waste into valuable fuel.

The raw materials for this process are as diverse as they are abundant: eucalyptus, birch, poplar, and various fruit trees, along with bamboo chips and crop straw. These materials are sourced responsibly, ensuring a minimal environmental footprint.

The transformation process is a marvel of engineering. It begins with the crushing of raw materials into smaller fragments. Then, through drying, the moisture content is reduced, making the material suitable for screening. The screened particles are then subjected to granulation, where they are compressed into dense, uniform pellets.

But the process doesn’t end there. Cooling is essential to stabilize the pellets, and packaging ensures they are ready for transport and use. The result is a high-quality, finished wood chip product that is versatile in its applications.

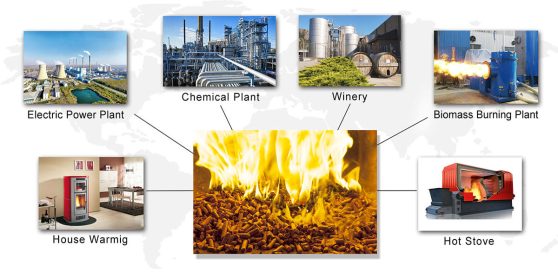

These wood pellets are not just another fuel; they are a testament to human ingenuity in the face of climate challenges. They power biomass power generation plants, provide heat for boilers, create a cozy ambiance in fireplaces, and are even used in household appliances.

As we continue to seek out renewable energy sources, the wood pellet machine’s role becomes increasingly vital. It’s a symbol of our commitment to a cleaner, greener future, where energy is produced harmoniously with nature.